Engineering clarity for regulated innovation in complex product ecosystems

Strategic Consulting for Device Design, IP Litigation, and FDA Regulatory Compliance

Industries and Stakeholders Supported

Regulatory and Product Development Teams

ENDS manufacturers, tobacco companies, and regulated product developers navigating FDA compliance, device engineering challenges, and PMTA submissions. Whether you're launching new products or defending existing ones, I bring executive-level product development expertise and regulatory strategy.

- •PMTA CMC section authoring and review

- •Device design optimization and risk mitigation

- •Cross-functional technical leadership

Legal Teams & Law Firms

Patent litigation attorneys, IP counsel, and legal teams requiring expert witness testimony and technical analysis for ENDS/vaping patent disputes. I provide comprehensive technical opinions, claim construction analysis, and courtroom testimony backed by 150+ granted patents and extensive industry experience.

- •Expert witness testimony for patent litigation

- •Prior art searches and invalidity opinions

- •Technical deposition preparation and support

Critical Outcomes Protecting Your Product

Regulatory Strategy Certainty

Eliminating the primary risk of Marketing Denial Orders (MDOs) by delivering authoritative CMC content. Transforming deep technical evidence into a defensible regulatory narrative that passes substantive FDA scrutiny.

Technical Litigation & IP Defense

Backed by 150+ patents, Bridging the gap between complex aerosol science and legal victory. Translating intricate device architecture into clear, courtroom-ready testimony that protects your core IP and secures favorable outcomes.

Manufacturing Integrity

Success isn't just about design; it's about ongoing consistency. Providing rigorous, post-market batch evaluations and factory QC audits to ensure your commercial product remains safe, compliant, and identical to your approved predicate.

Technical and Strategic Capabilities

Comprehensive expertise across the product development lifecycle

- •PMTA CMC Authoring & Review

- •Regulatory Risk Audits

- •Sustaining Engineering & Batch QC

- •Post-Market CMC Integration

- •Heater & Aerosol System Design

- •Thermal Management & System Control

- •Design Controls & Risk Management

- •Manufacturing & Quality Systems

- •Expert Witness Consulting

- •Patent Analysis & Opinions

- •Technical Due Diligence

- •Comprehensive device evaluations

- •Deposition & Trial Preparation

Sustaining Success: The Batch Integrity Program

Protecting Your Market Access Post-Approval

A successful PMTA is the starting line. Manufacturing drift is a major regulatory liability.

Statistical and technical verification that every production batch remains within the validated specifications of your original design.

Auditing and refining on-site Acceptance Test Procedures (ATP) to ensure overseas manufacturing maintains the integrity required for compliance.

Expert technical deep-dives into manufacturing deviations to mitigate risk and prevent failures before they reach the consumer.

150+ U.S. Patents

20+ Years Industry Experience

Zero MDOs on supported submissions

Startup to Fortune 500 support

Proven Industry Authority

Decades of Innovation Leadership

With over 150 U.S. patents and extensive experience leading product development at Fortune 500 companies, I provide unparalleled expertise in navigating the complex intersection of engineering, regulation, and intellectual property.

My track record includes successful PMTA submissions, strategic patent portfolio development, and expert testimony in high-stakes litigation cases.

Comprehensive Systems Engineering Expertise

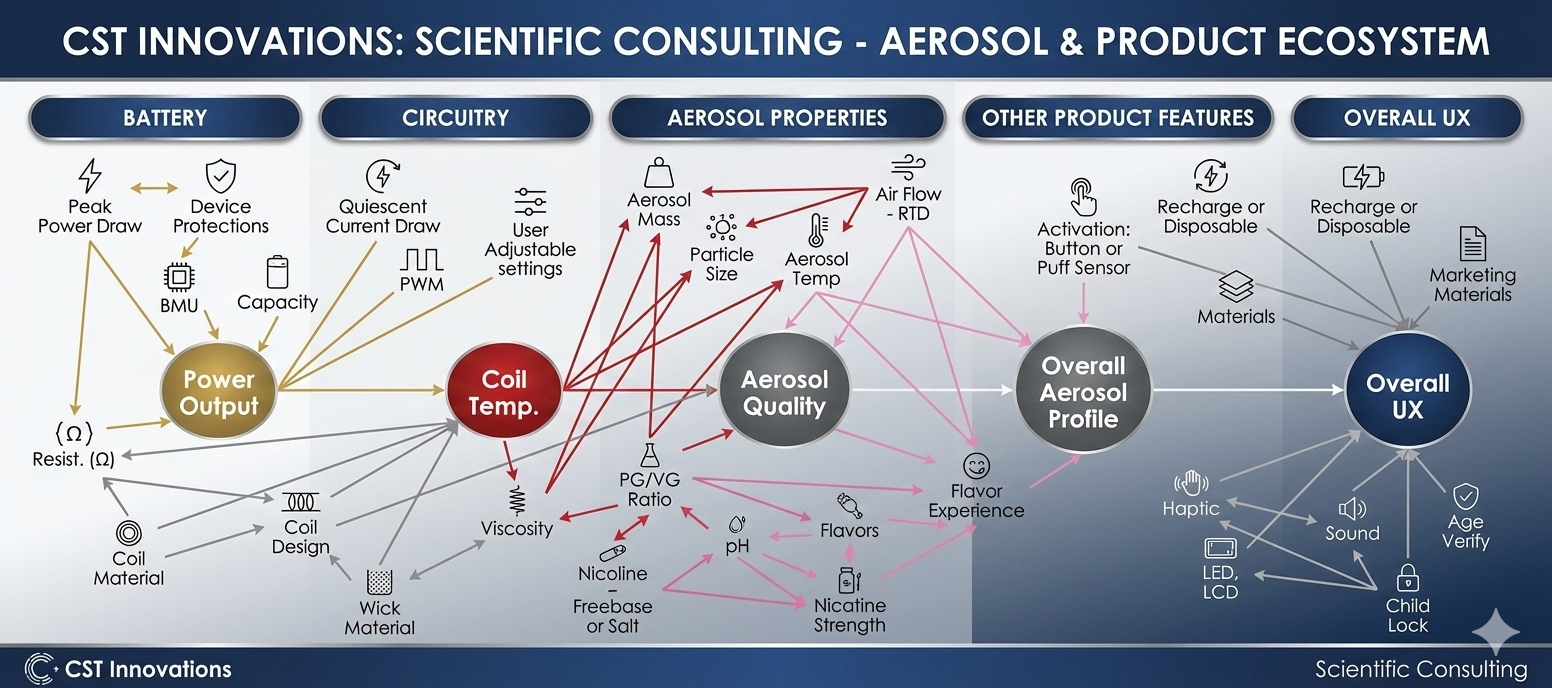

ENDS devices are highly integrated systems where every design decision matters. Battery, circuitry, heater technology, aerosol chemistry, and user interaction are tightly linked, and small changes can create outsized impacts on performance, compliance, and risk.

With over 20 years of experience across the full ENDS product ecosystem, I provide system-level engineering insight that supports defensible regulatory submissions, sound IP strategy, and robust product development.

Core Technical Competencies

Expert Device Teardown Analysis

Systematic teardown methodology for patent analysis, competitive intelligence, and PMTA documentation

Comprehensive expertise across all major heater technologies and wicking systems

Comprehensive Engineering Analysis - Systematic device teardowns provide critical insights for patent analysis, competitive intelligence, and PMTA documentation.

My detailed teardown methodology includes complete component identification, material analysis, assembly process documentation, and manufacturing technique assessment. This thorough approach reveals:

- Patent Landscape Analysis - Identify potential infringement risks and opportunities for freedom-to-operate

- Competitive Intelligence - Understand competitor design strategies, material choices, and cost optimization techniques

- Regulatory Documentation - Generate precise technical specifications required for PMTA submissions and SE reports

- Quality & Safety Assessment - Evaluate manufacturing quality, identify potential failure modes, and assess regulatory compliance

- Design Optimization - Uncover innovative engineering solutions and identify areas for product improvement

With decades of experience in device design and engineering, I provide expert analysis that bridges technical understanding with legal and regulatory requirements. Every teardown includes detailed photography, dimensional measurements, material identification, and comprehensive technical documentation suitable for litigation support or regulatory submissions.